- Online only

$945.00 Kit

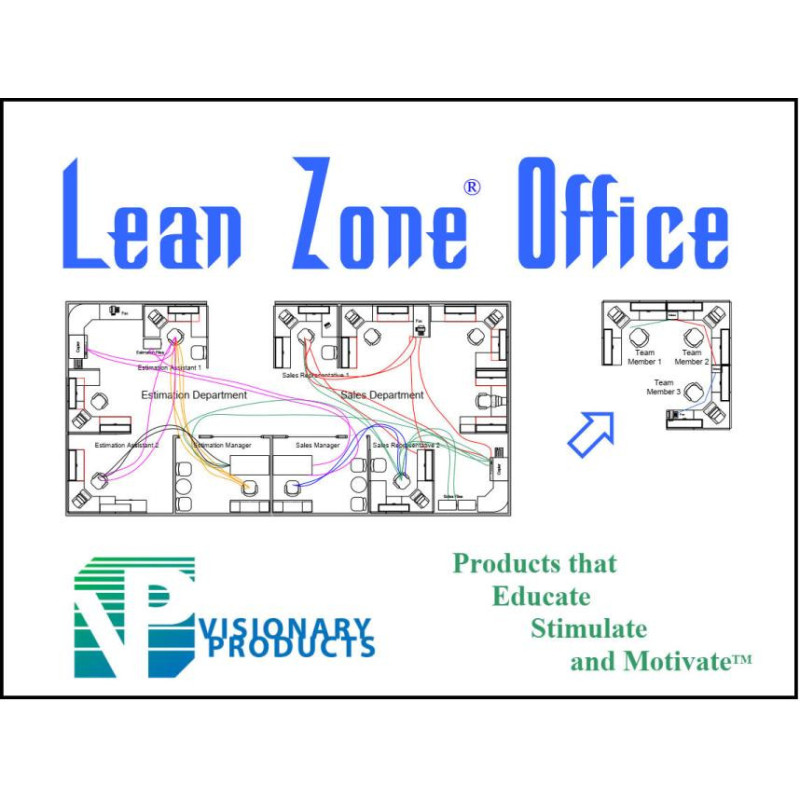

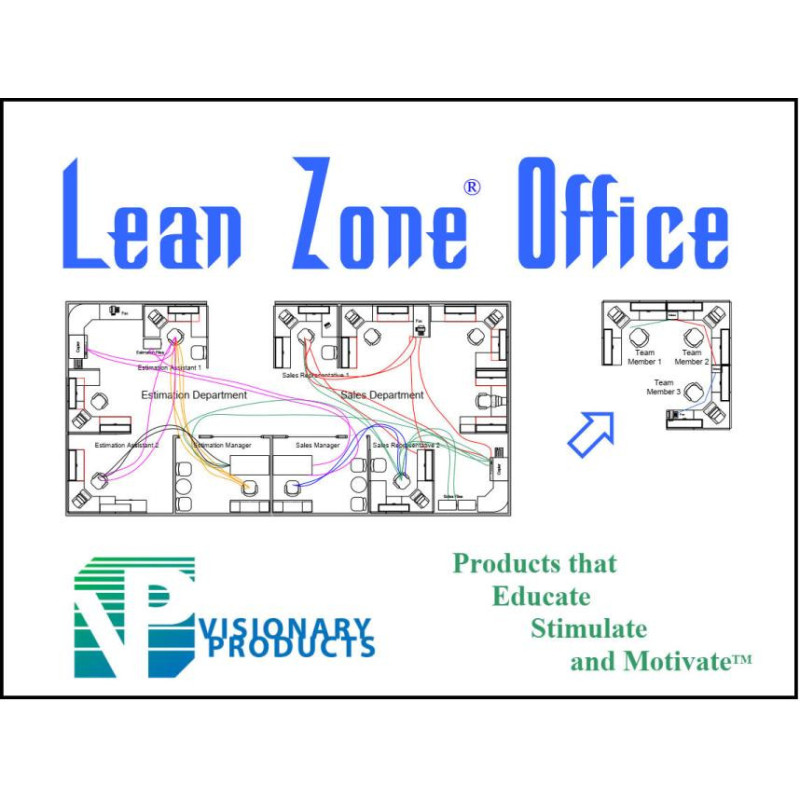

Lean Zone® Office puts participants to work in a fictional company where they experience change as a positive force by working to improve upon a traditional quotation process.

Shipping policy

Gurantee

Office processes are composed of individual tasks. These processes are generally developed over many years and normally contain steps that are no longer required. A lean office is one where each of these processes has been evaluated and streamlined for maximum efficiency. Wasted movement is eliminated by locating the personnel necessary to perform the task together.

This three-hour office efficiency simulation is divided into four phases. Seven participants are put to work in a fictional company called Widget Works, where they are asked to process quotations. Participants begin with a traditional quotation system, and are gradually introduced to lean principles that streamline the process.

Paper forms are used to simulate completing internal forms or data entry. Faxing and copying are simulated by filling in a brief form at the simulated copy/fax machine. Filing, gaining approvals, and retrieving supplies require the participant to walk around the room simulating normal footsteps in an office process. All of these activities are reviewed as potentially non-value added. The improvements made during the simulation represent changes that can be made to any office procedure. Changes are measured and discussed after each round.

It's ideal in the boardroom, training center, or the classroom.

Lean Zone® Office quickly teaches your employees concepts such as cellular layout, elimination of non-value added steps, one-piece workflow, pull systems, work balancing, cross training and flexible workforce. They will see why lean office is necessary and desirable. It should help remove their fears and encourage them to identify non-value added activity. The simulation kit includes step-by-step instructions for leading the simulation, along with an 88-slide Microsoft® PowerPoint presentation, plus all the materials needed for seven participants. Everything you need is in one, easy-to-transport package. The complete kit is priced at only $945. We ship internationally!

Lean Zone® Office applies the same successful principles used in lean manufacturing to the office environment. Participants work in a fictional company where they are introduced to lean practices and experience change as a positive force. In as little as three hours, employees learn concepts such as cellular layout, elimination of non-value added steps, work balancing, cross training and flexible workforce.

Overview: Most office processes can be completed in one continuous flow. In many offices, the paperwork moves between different areas of the offices where a different individual adds on the next part of the process. Office demonstrates how to design a work cell containing all the equipment and personnel necessary to complete the paperwork in one continuous flow. Once the cell is designed, one-piece flow and work balancing are introduced in increase throughput and eliminate piles of paperwork in in-baskets (work-in-progress). The simulation also has a final round that shows how to change staffing and work balancing for the process, based on demand changes.

Main teaching points: Cellular Layout, One Piece Flow with a Pull System, Work Balancing (Flexible Work Force), Elimination of Non-Value-Added Steps, Lead Time Reduction, and Rapid Throughput

Other lean concepts: Traditional Office Layout versus Cellular Layout, Standardized Approvals, Point of Use Storage, and Independent Cross Training

7 participants per kit

3hrs duration

Data sheet

Specific References

You might also like